SOLAR FARM Conduit Supplier

PVC and HDPE conduit, elbows, and couplers for utility scale solar farms and solar-plus-storage projects.

Reliable PVC & HDPE Conduit Solutions for Solar Farms

Central Conduit supplies UL certified PVC and HDPE conduit, long radius elbows, and couplers for large solar farms and solar-plus-storage projects. We work with EPCs, solar contractors, and procurement teams to keep underground collection systems, MV feeders, and interconnect runs moving on schedule from the first array block to final substation tie-in.

When schedules tighten and specifications cannot be compromised, our team responds fast; manufacturing, bending, and shipping conduit to meet demanding milestones. From standard Schedule 40 and 80 PVC conduit to custom radius PVC sweeps and emergency procurement solutions, Central Conduit provides reliable supply, expert support, and consistent quality for every solar project.

Quick Answer for Emergency Conduit Needs

Central Conduit supplies UL 651 and NEMA TC-2 PVC conduit, sweeps, and custom radius sweeps in 2 to 8 inch trade sizes for utility scale solar farms across the United States.

We step in when underground DC or AC collection work is waiting on conduit, often producing and shipping thousands of elbows within days using overtime crews and expedited flatbeds. If your trench is open and the schedule cannot slip, we treat your order as a 911 conduit run, not just another PO in the queue.

Quick Answer For EPCs And Electrical Contractors

Why Solar Farms Use So Much Conduit

Utility scale solar farms are spread across hundreds or thousands of acres. Every new array block, inverter skid, and substation means more underground raceways that have to be protected by conduit.

PVC and HDPE conduit, long radius elbows, and couplers show up everywhere on these projects: DC collection circuits from combiner boxes to inverters, AC feeders from inverters to the substation, medium voltage lines, communication runs, and spare ducts for future capacity. When conduit is late, wrong, or short on fittings, trenching and cable crews stop moving and the schedule starts slipping.

Conduit Requirements For Utility Scale Solar And Solar-Plus-Storage Projects

Utility scale solar and storage projects are not simple ground mount jobs. Higher DC voltages, larger inverters, and long runs between array blocks and the substation all roll downhill into the collection system and conduit plan.

Central Conduit packages PVC conduit, long radius elbows, custom radius sweeps, and HDPE conduit so solar farms and storage projects get a coordinated conduit plan instead of piecemeal material from multiple distributors.

Conduit Products For Solar Farms

PVC Conduit

UL certified Schedule 40 and Schedule 80 PVC conduit is the backbone of most solar farm underground DC and AC runs.

Common project trade sizes from 2 in through 8 in, supplied in 10 ft and 20 ft lengths to match your trench layouts, array block routes, and substation duct banks.

PVC Elbows and Fittings

PVC elbows handle the turns where solar collection and feeder circuits change direction

We supply standard and long radius elbows in the trade sizes used on DC collection, inverter approaches, road crossings, and substation duct banks, helping reduce cable stress and keep pulls clean.

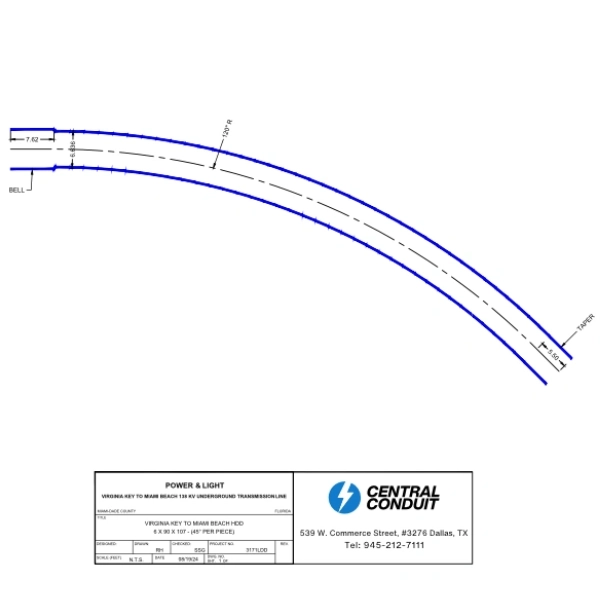

Custom Radius PVC Sweeps

PVC custom radius elbows made in any size, any radius, and any quantity for solar farm collection systems and substation approaches. Shaped to match your cable schedule, we have produced bends up to 150 feet for long runs between inverter pads, switchgear, and the point of interconnect.

Designed for smooth cable transitions, these bends reduce friction and tension, making wire pulls easier and safer.

HDPE Conduit

We supply HDPE in reels or sticks with options for striping and pull tape, designed to work alongside PVC so your collection system and communications raceways stay consistent across the site.

Conforms to domestic standards preference including Buy America (BAA), Build America, Buy America (BABA), and DOT Buy American requirements.

Solar Farm Conduit Spec Snapshot

Solar farm underground systems are not generic utility work. Most of the conduit we supply for utility scale sites falls into a few repeatable patterns. This snapshot shows how PVC and HDPE conduit, elbows, and custom sweeps are typically used on solar projects.

Central Conduit plans shipments around your build sequence so conduit, sweeps, and couplers arrive when the trench, inverter pad, or substation duct bank is ready. We coordinate with your site team and freight partners to cut down on idle trucks, missed appointments, and crews standing around.

| Use Case | Product | Material | Schedule | Trade sizes | Typical length | Standards |

|---|---|---|---|---|---|---|

| DC collection from arrays to inverters | Straight PVC conduit | PVC | Sch 40 / Sch 80 | 2 – 8 in | 10 ft / 20 ft | UL 651, NEMA TC-2 |

| AC feeders from inverters to substation | Straight PVC conduit | PVC | Sch 40 / Sch 80 | 2 – 8 in | 10 ft / 20 ft | UL 651, NEMA TC-2 |

| Substation and interconnect duct banks | Straight PVC conduit and Sweeps | PVC | Sch 40 / Sch 80 | 2 – 8 in | Sticks or sweeps | UL 651, NEMA TC-2 |

| Road crossings and terrain transitions | Long Radius PVC Sweeps | PVC | Sch 40 / Sch 80 | 2 – 8 in | 24 – 96 in radius | UL 651, NEMA TC-2 |

| Long runs between array blocks and substation | Custom Radius PVC Sweeps | PVC | Sch 40 / Sch 80 | 2 – 8 in | 96 in up to 150 feet radius | UL 651, NEMA TC-2 |

| Fiber, SCADA, and communications | HDPE Conduit | HDPE | SDR 11 / 13.5 / 17 | 1 – 6 in | Reels or sticks | ASTM F2160, UL 651A, NEMA TC-7, BABA compliant |

| Joining PVC conduit | PVC couplers | PVC | Sch 40 | 2 – 8 in | Long line, 5° flexibility | UL 651, NEMA TC-2 |

Proven On Utility Scale Solar Projects

500 MW Utility Scale Solar Farm – Yuma, AZ

Ready To Talk About Your Solar Farm Project?

Bring Central Conduit onto your next solar farm or solar-plus-storage project.

Standards And Specs For Solar Farm Conduit

PVC conduit and elbows for solar farms must meet the same electrical standards as any critical power installation, but at much larger horizontal scale. Central Conduit supplies Schedule 40 and Schedule 80 PVC conduit and fittings manufactured to UL 651 and NEMA TC-2 requirements, covering material, dimensions, impact resistance, and performance for above ground, encased, and direct burial use.

For HDPE conduit used on fiber, SCADA, and communication runs, we work with products that meet ASTM F2160, UL 651A, and NEMA TC-7. These standards govern dimensional tolerances, pressure ratings, and long term performance for underground and directional drilling applications, which is why project engineers and inspectors recognize them on submittals and as-built documentation.

Logistics For Live Solar Farm Projects

Solar farms are often remote, exposed, and spread over large areas. Access roads, weather, and limited laydown mean PVC and HDPE conduit deliveries have to match the construction schedule, not fight it.

Central Conduit plans shipments around your build sequence so conduit, sweeps, and couplers arrive when each trench, inverter pad, or substation duct bank is ready. We coordinate with your site team and freight partners to cut down on idle trucks, missed appointments, and crews standing around.

Bill Of Materials Review For Solar Farm Conduit

We review solar farm conduit bills of material for PVC and HDPE, looking for missing sweeps, elbows, mismatched radii, and unrealistic delivery assumptions.

Send your current takeoff or conduit schedule and we will flag risk areas and suggest a shipment plan that keeps trench work and cable pulls moving.

Mention BOM review in your request.

Who This Is Not For

We are not a fit for small rooftop or carport solar jobs needing a few sticks of conduit. Our solar farm conduit programs are designed for utility scale sites, solar-plus-storage projects, and large interconnects that measure conduit in truckloads, not cart loads.

Who We Work With On Solar Farm Projects

Central Conduit is built for teams responsible for keeping solar farm schedules on track. We supply PVC and HDPE conduit, elbows, and couplers to the people who own the trench, the collection system, and the milestones.

How Different Teams Use Us On Solar Farm Projects

Conduit For Solar Farms FAQ

Emergency 911 Conduit Procurement Service

When underground work is waiting on conduit, you do not have weeks to spare. Our Solar Farm Conduit 911 Package is built for live sites where trench work, backfill, or cable pulls are at risk of slipping.

We mobilize emergency production and logistics for PVC conduit, sweeps, custom radius PVC sweeps, couplers, and other installation tools.

If your solar farm project is exposed because conduit or elbows did not arrive as planned, the Emergency 911 Conduit Procurement Service gives you a way to recover schedule without gambling on the general supply chain.