Telecom And Fiber Conduit Supplier

HDPE conduit, MicroDuct, FuturePath, and PVC transition fittings for telecom and fiber projects that need reliable underground pathways.

Telecom And Fiber Conduit Supplier For Backbone, Metro, And FTTx Projects

Central Conduit supplies HDPE conduit, MicroDuct, FuturePath, and PVC transition fittings for telecom and fiber projects. We support carriers, ISPs, fiber builders, and underground contractors on backbone routes, metro rings, FTTx builds, 5G backhaul, and data center interconnects.

For these projects, HDPE is the backbone. Smoothwall, Smooth Out / Ribbed In, UL 651A sticks, and NEMA TC-7 conduit handle the long runs, directional bores, and congested corridors. PVC shows up at vaults, manholes, central office entrances, and structures where rigid duct banks are required.

We build your telecom package around HDPE as the primary system, then match in PVC elbows, sweeps, and couplers where the spec calls for it. The result is a coordinated HDPE and PVC solution that your engineers and inspectors recognize and your fiber crews can pull through.

Quick Answer For Emergency Telecom Conduit Needs

Central Conduit supplies HDPE conduit, MicroDuct, and FuturePath, plus PVC transition fittings, when routes are already under construction and work windows are booked.

For active routes, we can:

If your trench, bore rig, or splicing crews are on the clock and conduit is missing, we treat that as a 911 HDPE problem and respond accordingly.

Quick Answer For Carriers, ISPs, And Fiber Builders

Why Telecom And Fiber Projects Lean On HDPE

Telecom routes are long, crowded, and expensive to reopen. That is why modern fiber builds lean heavily on HDPE conduit systems:

Dura-Line HDPE conduit is designed for these conditions. Flexible HDPE Smoothwall and ribbed wall products make gradual bends without special fittings, protect cables from shifting ground and rock, and can be supplied in long continuous reels that reduce joint counts.

PVC remains important at manholes, vaults, and building entries, but HDPE is the workhorse that carries fiber across the distance.

Conduit Requirements For Telecom And Fiber Networks

Telecom builds are built around fiber bend radius, cable jetting distance, and route congestion. The conduit system has to support that.

Central Conduit maps these Dura-Line HDPE options to your route design. Backbone segments, metro rings, laterals, and vault approaches each get the HDPE or PVC product that matches the spec, installation method, and future growth plan.

SDR and wall thickness for HDPE conduit

HDPE conduit is manufactured in multiple Standard Dimension Ratios (SDR), which is simply the ratio of the pipe diameter to the wall thickness. Lower SDR numbers mean a thicker wall and higher pressure and crush resistance, while higher SDR numbers use less material and are lighter and more flexible.

On telecom and fiber projects, SDR is usually chosen based on:

We work with your spec or engineer of record to select the SDR combinations that match each segment of your route so you are not overbuilding in one area and underbuilding in another.

Conduit Products For Telecom And Fiber Projects

HDPE Smoothwall, UL 651A, MicroDuct, FuturePath, Smooth Out / Ribbed In

HDPE conduit comes in several styles to match different telecom routes and installation methods, including HDPE Smoothwall, UL 651A listed electrical HDPE, MicroDuct and FuturePath bundled MicroDuct systems, and Smooth Out / Ribbed In designs for lower friction cable pulls. Together these options let you choose the right combination of wall profile, SDR, and internal duct configuration for long backbone runs, directional drilling, dense metro corridors, and future expansion.

PVC Conduit

PVC is still the preferred material for rigid duct banks into vaults, central offices, POPs, and data centers. We supply Schedule 40 and 80 PVC, elbows, and sweeps at these locations and coordinate the transition from HDPE outside the structure to PVC at the entry and inside the duct bank.

Common telecom trade sizes from 2 in through 6 in, supplied in 10 ft and 20 ft lengths to match your duct bank and vault layouts. On routes that tie into data centers, the same sizes can be used at the entries.

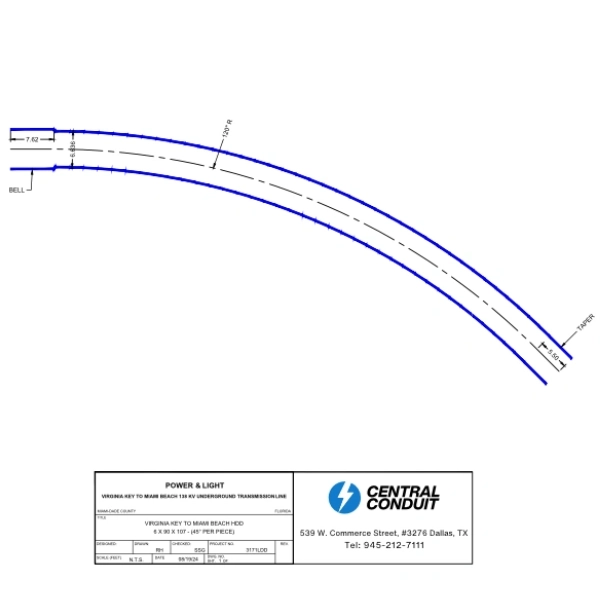

Custom Radius PVC Sweeps

PVC custom radius elbows made in any size, any radius, and any quantity for vault approaches, central office and POP duct banks, and data center interconnects. Shaped to match your cable schedule, we have produced bends up to 150 feet for long runs between substations, hubs, and data halls.

Designed for smooth cable transitions, these bends reduce friction and tension, making wire pulls easier and safer.

Telecom And Fiber Conduit Spec Snapshot

Here is how HDPE and PVC typically line up on a telecom or fiber project.

Central Conduit plans shipments around your build sequence so elbows, conduit, and couplers arrive when the trench, vault, or duct bank is ready. We coordinate with your site team and freight partners to cut down on idle trucks, missed appointments, and crews standing around.

| Use case | Product | Material | Type | Typical sizes | Typical format | Standards |

|---|---|---|---|---|---|---|

| Backbone and metro fiber routes | Smoothwall or Smooth Out / Ribbed In | HDPE | Standard or ribbed wall | 1 – 4 in | Reels or sticks | ASTM F2160, NEMA TC-7, SDR 11 / 13.5 / 17, UL 651A where required |

| Long directional bores | Smooth Out / Ribbed In, Ribbed In / Out | HDPE | Ribbed wall | 1 – 4 in | Reels | ASTM F2160, NEMA TC-7, SDR 11 / 13.5 for higher strength in HDD applications |

| Dense fiber corridors and future capacity | MicroDucts, FuturePath bundles | HDPE | Bundled MicroDuct | 5 – 27 mm OD MicroDucts | Multi-way bundles | Engineered SDR per bundle configuration; internal ribs and lubricated lining optimized for jetting |

| Vault and manhole approaches | PVC conduit and sweeps | PVC | Sch 40 / Sch 80 | 2 – 6 in | 10 ft / 20 ft sticks | UL 651, NEMA TC-2 (schedule-based, not SDR) |

| Data center and central office entries | PVC conduit, sweeps, HDPE transitions | PVC / HDPE | Sch 40 / Sch 80, UL 651A | 2 – 6 in | Sticks and transitions | UL 651 (PVC), UL 651A (HDPE), NEC 353; HDPE transition pieces typically SDR 11 |

Ready To Talk About Your Telecom Fiber Installation Project?

Bring Central Conduit Onto Your Project

Standards And Specs For Telecom HDPE

Telecom HDPE has to satisfy both telecom and electrical expectations when it shares corridors with power.

We match these standards to your spec sections so submittals and inspections go smoothly.

Logistics For Live Telecom Projects

Telecom and fiber routes do not move like palletized warehouse freight. You are dealing with reels, sticks, MicroDuct bundles, and couplers that have to arrive in the right sequence for trenching, boring, and pulling.

Central Conduit: